With a little over 2200 hours on this set of injectors and a good amount of light smoke on startup, it was time to rebuild the injectors. Normally I would pull them, drop them off at the local diesel shop and pick them up a few days later. Labor, new nozzles and the consumable seal rings, I was usually out the door for $50 per injector.

This time around I wanted to see if I could do the work myself. With a little research I found the pressure spec they needed to pop at, and all my part numbers.

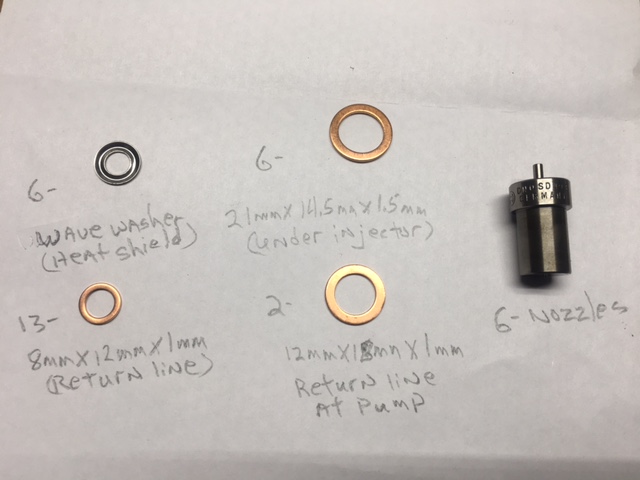

The nozzles were the easiest part to find. Denso DN0SD193 was on the side of my old nozzles. that is the same nozzle as Bosch 0434250063 and I found them at RockAuto.com for $10.80 each.

The three sizes of copper washer I needed came off Ebay for around a dollar each. I just used a micrometer to find my sizes.

I needed 6-14.5mm X 21mm X 1.5mm to seal the injector to the head. 13-8mm X 12mm X 1mm for the return line banjo bolts and 2-12mm X 18mm X 1mm for the return line banjo bolt at the pump.

The hardest part to find was the heat shied washer that goes in the injector hole to insulate the injector tip from the head. The only part number I could come up with was off a Volvo parts site, 1542158 for $5.80 each. I ordered them through a Volvo rep, and 5 weeks later they still can't give me an estimated shipping date. I saw a lot of different sized heat shield washers on the internet, so I used the micrometer to figure out what size I needed. They measured 13.8mm x 6.4mm x 1.2mm, and that turned out to be a Bosch 2430190002 seal ring. I found a shop in Italy that sells on Ebay, so I ordered 20 for less than 80 cents each.

The last thing on my list was the nozzle tester. There are a lot of sub $100 testers on the market. They are nothing more than a glorified bottle jack with a gauge and some injector fittings. Most are made in China or India with gauges ranging from 0-4000 to 0-10000 psi. I was looking to test in the 2400-2700 psi range so I went with one I found on Ebay, coming out of India. I didn't expect much for $80, but it got the job done. I can see some areas that could be improved upon, like a better gauge and pump. I have a bigger 0-4000 glycerin filled gauge on the way and plan on replacing the jack with my porta-power pump.

On the first set I rebuilt this week, I had 2 that were popping a coupe hundred pounds high. I had to hone .005 off the shim washer under the spring to bring them into spec.

The second set has 2 that were popping a couple hundred to low. I has to add .003 to one and .005 to the other to bring them up to spec.

Reply With Quote

Reply With Quote